A Primer for Claims and Disputes (Claims 101)

By John Ciccarelli, PE, CCP PSP FAACE

Introduction

The AACE International Claims & Dispute Resolution Subcommittee (“CDR Subcommittee”) is a group of professionals and experts actively involved in the preparation, analysis, management, mitigation, and resolution of claims and disputes on projects. The general purpose of the CDR Subcommittee is to provide a neutral, professional forum where professionals involved in the claims and dispute process can meet, discuss, and develop technical content about issues of common interest. These claims-related issues are typically focused on the analyses of schedule delay, disruption, and damages quantification, which also include assessments of entitlement and responsibility.

While the CDR Subcommittee is dedicated to claims and disputes, many of the other AACE International technical functional areas become a component of the various claims analyses. For example, some of the AACE technical subjects that are frequently addressed during a claims analysis include:

- Contract Management

- Cost Estimating

- Decision and Risk Management

- Earned Value

- Planning and Scheduling

- Project and Cost Control

- Value Management

As such, it would be useful for practitioners in these subject areas to be more familiar with claims and disputes and how their work product could influence the analyses typically performed in claims on which experts often rely. The balance of this article serves as an introduction to and primer for claims and dispute resolution for professionals interested in this practice area.

Background

Claims and disputes are different albeit related issues. The definition for each term represents that a dispute is a general disagreement, while a claim involves a more formal process, including written demands. [1]

- Dispute – A disagreement between the owner and the contractor as to a question of fact or contract interpretation which cannot be resolved through negotiations to the mutual satisfaction of the parties.

- Claim – A demand or assertion of rights by one party against another for damages sustained under the terms of a legally binding contract. Damages might include money, time, and/or other compensation to make the claimant whole. Claims can also request relief from contract requirements (i.e., liquidated damages).

While the above definitions suggest the dispute or claim is between an owner and contractor, disputes often involve other parties, including designers, subconsultants, construction managers, subcontractors, insurers, and funding partners, among others. The nature and involvement of parties will be determined by the project delivery method and form of contract agreement. Examples of project delivery methods include design-bid-build, EPC, and design-build). Examples of contracts include variations of cost-plus fee and fixed price (i.e., guaranteed maximum price and lump sum).

An important document referenced in each of the above definitions is the contract, or the legal agreement between the parties. The contract typically includes the following types of documents: the agreement and addenda; general, special, and supplemental conditions; technical specifications, plans, and drawings; contractor’s proposal and bid; and other documents specifically referenced in the agreement. In a typical design-bid-build model for construction, the owner hires a designer to prepare the contract documents in accordance with industry standards. The owner then procures a contractor to construct the project as described in contract documents. Contractors bid on the project based on their planned project execution means and methods with the expectation that the design documents are complete and any material variations will be paid via change orders.

With respect to claims and disputes, there are key clauses, concepts, and requirements that the contract should address, and which project participants must read, understand, and follow. The clauses for these key subjects are usually found in the general conditions and include:

- Changes/Claims – Understand the process for managing change orders and time extensions and the requirements for initiating the dispute or claim process, as well as escalating the decision. [2]

- Time/Schedule Requirements – Understand the project milestones, applicable liquidated damages, “time is of the essence” or “no damage for delay” clauses, time extension analysis methodology, and the scheduling technical aspects, including requirements for critical path method (CPM) scheduling, baseline schedule, level of detail, relationships, float, activity coding, report preparation and formatting, and recovery scheduling.

- Notice – Follow the contract requirements for notification when a potential change or event has occurred and any follow up actions. If a notification deadline is missed, a claim is at risk of being denied.

- Force Majeure – Unanticipated events that impact the work and over which neither party has control, (i.e., acts of war, weather, strikes, and other events specified in the contract).

Disputes and claims typically arise when a change is encountered within the context of the contract and the parties cannot come to an agreement on the issues being negotiated.

Causes of Claims and Disputes

Disputes and claims can be caused by numerous reasons, including but not limited to:

- Scope/Unresolved Changes

- Differing Site Condition

- Restricted Site Access

- Design Errors and Omissions

- Revised Regulations

- Incomplete or Late Design

- Ambiguous Documents (Spearin Doctrine)

- Unusually Severe Weather

- Added Work by Owner

- Delays in Owner Procured Items

- Low Productivity/Cumulative Impact

- Owner/Inspector Interference

- Work Suspension

- Acceleration (Constructive)

- Interference by Other Trades or Contractors

- Third party (Utility) Interference

- Shortage of Skilled Labor

- Contractor Performance (Workmanship, Quality)

Typical Claim and Dispute Resolution Process

Most contracts provide a process for initiating and resolving disputes including the venue, jurisdiction, and forum for conducting proceedings. In general, the processes include a decision maker and can be categorized into a self-decided group or adjudication.

- The decision maker concept typically involves the designer as an initial decision maker on a submitted change order or disputed issue on the project.

- The self-decided group of dispute resolution processes are typically resolved at the project level in which the parties have a say in the decision. These options include:

- Avoidance – most, if not all avoided disputes become bigger problems and do not self-resolve.

- Negotiation – between the parties and involves only the parties. Negotiations at the project level can be casual — conducted through conversations, emails, texts, and phone calls, or can be formal with meetings, documentation, and presentations.

- Mediation – parties voluntarily bring in a respected, neutral, uninvolved third-party to facilitate reaching a mutually acceptable resolution. Mediators do not decide or rule on the matter, but instead work with the parties to facilitate an agreement.

- Dispute Review Board (DRB) – typically a process defined in the contract, with three neutral members on a panel who decide on disputed project issues in a timely manner. The DRB members conduct regular site visits and hearings as needed.

- The adjudication group of dispute resolution processes are those in which someone else decides the fate of the matter. The adjudication options include:

- Arbitration – the submission of a dispute to one or more impartial persons (typically familiar with the construction industry) for a final binding (sometimes non-binding) decision on the case, known as an “award.” The awards are usually made in writing.

- Litigation – the claim is brought before a federal or state agency in the form of a lawsuit and is adjudicated in a courtroom with a judge and/or jury decision in a trial. This process can be long and slow, with exposure to appeals.

Regardless of the dispute resolution process method used, the practices to manage, document, demonstrate entitlement, analyze, and quantify claims are similar. As discussed earlier in this article, the contract should identify required information to be submitted with a change order or claim, including a time impact analysis and detailed cost records. Failing to follow the process can result in losing the opportunity for recovery.

Elements of a Claim

Generally, it is the claimant’s responsibility to prove a claim. AACE International Recommended Practice (“RP”) 120R-21, Demonstrating Entitlement for Contract Change Orders or Claims – As Applied in Engineering, Procurement, and Construction, is a primary technical resource that addresses necessary elements to determine technical entitlement and provides guidelines concerning the various elements to be considered for use in developing a change order or claim. As such, a change order, variation, claim, or REA submittal package should include and address the following elements:

- Establish Entitlement – Entitlement has two perspectives: legal and technical.

- From a legal perspective, first and foremost, counsel should be consulted to frame the challenges and requirements for establishing entitlement to reimbursement for the disputed issue. Claims practitioners should understand and consider a disputed issue in the context of the contract, applicable laws, regulations, notice provisions, and the dispute resolution process.

- The technical perspective of a disputed issue considers the contract scope of work to confirm the issue was out of scope or was a change order. Most contracts identify the required technical material and analyses to accompany a claim submission and calculate additional time and costs (i.e., supporting analyses, cost support, and documentation).

- Demonstrate Causation and Responsibility – this element should be the most technically focused effort to develop various cause and effect analyses to establish the causal linkage (nexus) between facts and events and the impacts in dispute. These analyses can include forensic schedule delay, loss of productivity (resulting from disruption), damages quantification, and other technical demonstrative analyses.

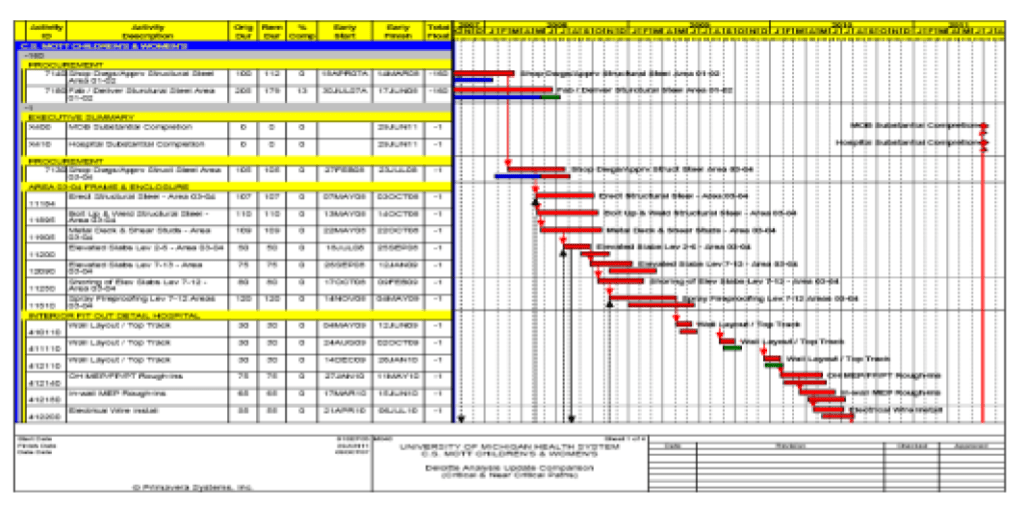

- Forensic Schedule Delay – disputes often include an element of delay, or an event or issue that “cause the work or some portion of the work to start or be completed later than planned or later than scheduled.” [1] A claim would be asserted for impacts that resulted in additional time that could increase the project duration, usually resulting in additional costs to both parties.

AACE International RP 29R-03, Forensic Schedule Analysis, is a primary technical resource that addresses the delay element of a claim and provides guidelines to the industry for the application of CPM scheduling in forensic schedule analysis to measure delay (including disruption and acceleration) and identify effected activities to focus on causation. The protocols detailed in RP29R-03 consider numerous factors, including:

- As-Planned Baseline Schedule

- Contemporaneous Schedule Progress Updates and Re-Baselined Schedules

- Nine Method Implementation Protocols for Analysis

- Concurrent Delay

- Critical Path and Float

- As-Built Data

- Factors for Choosing a Method

Overall, a forensic schedule delay analysis will determine whether a delay was excusable or non-excusable, and then if excusable, whether the delay is compensable or non-compensable.

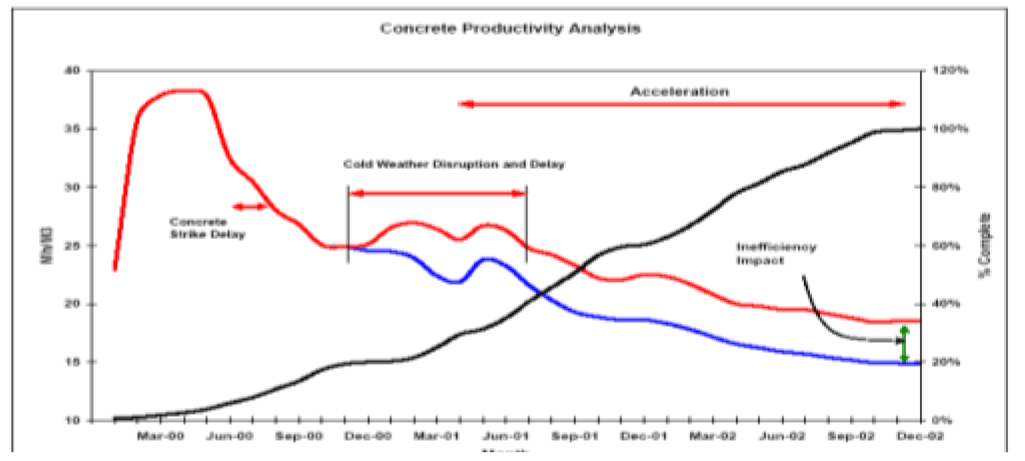

- Loss of Productivity – another element of disputes and claims, tied to both delay and damages, is an assertion for impacts resulting from loss of productivity (“LoP”). Claims for LoP can be contentious, and the effect on cost and schedule difficult to identify and quantify. Often, LoP occurs as the result of a disruptive event or series of events. Disruption is defined as “[…] an interference (action or event) with the orderly progress of a project or activity(ies) […] the effect of change on unchanged work and manifests itself primarily as adverse labor productivity impacts […].” [1]

AACE International RP 25R-03: Estimating Lost Labor Productivity in Construction Claims is a primary technical resource that addresses the LoP element of a claim and provides guidelines to the industry for the application of analyses related to capturing the effect of LoP on cost and schedule. The methods detailed in RP25R-03 consider numerous factors, including:

- Industry definitions of productivity (i.e., rate of production; output per unit of input) and LoP (actual productivity is less than that which could have been achieved under as-planned normal working conditions).

- Common causes of LoP.

- The project control records that are available, specifically for labor and quantities installed, to facilitate selecting an estimating method; and

- The various analysis methods employed, including project specific analyses (i.e., measured mile, earned value analysis, direct observation), specific industry studies (i.e., acceleration, overtime, cumulative impact, and weather), and general studies (i.e., MCAA, Construction Industry Institute, Leonard Study), and cost-based methods.

- There are other technical demonstrative analyses that are used to establish causation of events to delay, disruption, and damage impacts. Depending on the type of data available in the project file, the following are example topics can be analyzed to support a claim:

- Change Orders – the timing, frequency, and magnitude of approved and rejected change orders.

- Shop drawings – the timing and approval turn-around, design revisions or scope creep, and recycle of submittals.

- Requests for Information (“RFIs”) – timing, frequency, disposition, and response time for RFIs and other design revisions.

- Quality – tracking workmanship and rework of scope (i.e., welding).

These analyses are often conveyed in tables, charts, graphics, and other illustrations to communicate the findings and demonstrate the causal nexus to the impact events in dispute.

- Quantify Damages – the culminating element in a claim is the quantification of damages that represent the additional costs incurred by the claimant resulting from the impact event. The claimed amounts to be considered as damages for reimbursement can include:

- Remaining unpaid contract balance and change orders (approved and un-approved), which may be comprised of direct project costs for labor, material, equipment, subcontractors, and consultants.

- Time-related indirect project costs for general conditions (i.e., field supervision, field office, trash, utilities, etc.).

- Home office overhead costs for home office staff, expenses, travel, legal, depreciation, and other corporate costs that were not directly allocated to the project.

- Interest, insurance, bond. And,

- Markup for profit.

The choice of a damage quantification methodology can be influenced by the available project records and data. Triers of fact have generally established that discrete approaches are more accurate and effective than the other cost-based methods. The damage quantification methodologies to be considered include:

- Discrete, project specific approaches, which can involve and rely on preparation of specific estimates for changes or extra work, a LoP analysis (i.e., measured mile analysis), “should have” cost estimates, earned value analysis, and industry standards (factors) and handbooks.

- The cost-based methods, while typically less accepted because of certain flaws, include the total cost method, modified total cost method, and quantum meruit approach.

- Documentation – the last, but definitely not least, underlying element to any dispute and claim is documentation. Supporting documentation is vital to each of the aforementioned elements and to developing a comprehensive and unimpeachable change order or claim submission. When a problem event emerges, it is a best practice to immediately document the issues, events, and facts through written notification while also collecting (or continuing to collect) relevant data. A dedicated file should be built, and cost account assigned for the issue and impacts inserted into the schedule as applicable.

Preparing the Claim

When a dispute transitions into a formal claim, there are additional parts of the process to understand while preparing to submit the claim. The process for finalizing and submitting a formal claim should consider:

- Understanding and adhering to contract claim requirements and deadlines. This includes preparing a timeline for development and filing the claim.

- Understanding the audience and venue for the dispute resolution proceedings.

- Drafting a narrative to articulate claim; confirm entitlement; demonstrate causation through forensic schedule, loss or productivity, and other technical analyses; and quantify damages.

- Engaging or consulting with counsel and an expert claims consultant experienced with construction disputes.

- Collecting, assembling, and preparing support documentation for the discovery and production process, including electronically stored information (“ESI”).

Conclusion

This article introduces the general concepts associated with claims and dispute resolution, the subject matter in which the CDR Subcommittee specializes. The goal is to provide various other AACE technical subject practitioners perspective into the claim process so they can better understand the influence that their work product could have on the various analyses typically performed in a claim and on which experts often rely. If you have interest in any of topics addressed herein, please reach out to CDR Subcommittee members or check the AACE Resource Library for technical papers and recommended practices published under the CDR Subcommittee banner.

REFERENCES

- AACE International, Recommended Practice 10S-90, Cost Engineering Terminology, AACE International, Morgantown, WV.

- AACE International Recommended Practice 100R-19, Contract Change Management – As Applied in Engineering, Procurement, and Construction, AACE International, Morgantown, WV.

Rate this post

Click on a star to rate it!

Average rating 4.8 / 5. Vote count: 19

No votes so far! Be the first to rate this post.