Earned Value Management Systems for Operations Activities

Dan Melamed, CCP EVP FAACE; Crystal Williams;

Lisa Ramdas; and Rodney Lehman

Abstract–An earned value management system (EVMS), which monitors contractor performance, is a requirement for program and project management for all major acquisitions by the United States Federal Government with development effort: (i.e., an asset requiring management attention because of its importance to an agency’s mission; high development, operating, or maintenance costs; high risk and/or high return).

As an area less explored in earned value management (EVM) practices, this paper will survey the application of an EVMS for operations activities defined as:

- Non-capital asset activities that are projects (or project – like) with definable start and end dates, with discrete scopes of work, and measurable accomplishments; as well as

- Routine or recurring facility or environmental operations.

This paper will examine the use of an EVMS to evaluate performance of operations and maintenance activities required once construction of a capital asset is complete and being used as intended. Such activities include upgrades and maintenance in order for capital assets to meet their mission function over a life-cycle (through repair, replacement, etc.).

This paper will provide background on this topic from the perspective of the Department of Energy (DOE) Environmental Management (EM) Program. In addition, it will provide material from a panel discussion provided by a group of experts from the October 2019 Office of Environmental Management Project Management Workshop, as well as material from subsequent research on this topic.

Introduction

This paper discusses the applicability for using an earned value management system (EVMS) for measuring performance of operations activities for government programs, specifically with a focus on the Environmental Management (EM) Program of the United States Department of Energy (DOE). EM was established by Congress in 1989 to manage the clean-up of areas where federal activities have contaminated the environment – such as nuclear weapons production facilities and military installations.

This paper will supply the necessary background to provide a better understanding for the role of operations activities in the management of project and program baselines as well as their budgets for the Environmental Management Program. The general requirements of an EVMS within the United States Government for capital asset projects and operations activities will be discussed. To support this effort, this paper provides definitions for both capital asset projects as well as operations and maintenance activities which very often coexist in environmental cleanup efforts and combine to form an EM program baseline.

The Government Accountability Office (GAO) – whose mission is to serve the Congress and the American people by collecting, analyzing, and reporting on information about federal programs and services was directed to review the EM program, with a focus on its management of operations activities. A summary of the results of their investigation, published in February 2019, stated “Until EM revises its cleanup policy to follow leading practices, EM’s operations activities are at risk of uncontrolled changes to scope, exceeding initial budget and schedule, and failing to meet their original goals.” [1, Highlights] As part of the response to this report, in October 2019, the EM Office of Project Management held a panel discussion by a group of experts on EVMS for operations activities during the Office of Environmental Management Project Management Workshop. The panel, listed in Appendix 1, consisted of one employee of the EM Program and four contractors, each with extensive experience with EVM and its application at a number of agencies, including previous experience at: National Aeronautics and Space Agency (NASA) and Department of Homeland Security (DHS). Their current work experience covers the following federal agencies:

- The DOE EM Program (described above);

- The National Nuclear Security Administration (NNSA) a semi-autonomous agency within the U.S. DOE, responsible for enhancing national security through the military application of nuclear science; [2, page 6] and

- The Assembled Chemical Weapons Alternatives (ACWA) – a United States Army program dedicated to the disposal of chemical weapons in a safe, environmentally sound, cost-effective manner. [3 pages 12, 22, and 87]

The panel members’ experiences with these technically challenging programs, would provide good insight for best practices for the use of EVM in operations activities that can be readily applied to the EM Program. The next sections discusses and expands upon some of the major points addressed during the panel discussion, along with extra information not discussed during the workshop. This includes a discussion of an industrial sector where EVM for operations has already been implemented: the shipbuilding industry.

The Advantages of Earned Value Management

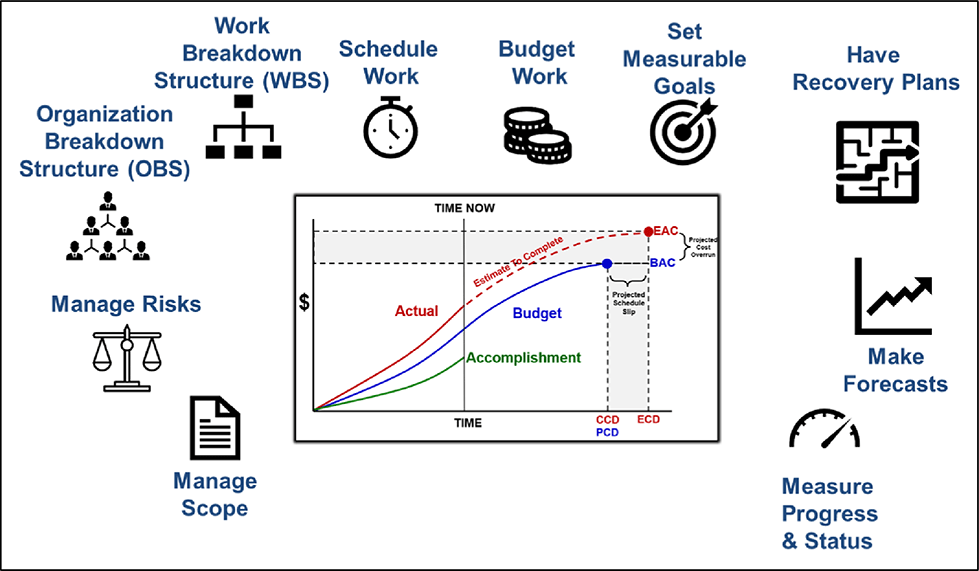

EVM provides a measurement of the work accomplished on a given project and/or program scope within a given period and compares it with the planned work scheduled for that same period along with the actual cost of work accomplished during that period of time. This provides improved understanding for project and program performance status, including an estimated cost and time to complete. In addition, EVM provides tools to manage risks, alerting management to potential problems and informing their forecasts to project completion. A general summary of what EVM enables is shown in Figure 1 (below).

Figure 1–A General Description of What Earned Value Management Enables.

[4, page 18]

Requirements for an Earned Value Management System in the Federal Government

An EVMS, is defined within the Recommended Practice (RP) 10S-90 Cost Engineering Terminology as a project progress control system that integrates work scope, schedule, and resources to enable objective comparison of the earned value to the actual cost and the planned schedule of the project. [5, page 46] This is required for many projects funded by the United States government to assure compliance with the Electronics Industries Alliance (EIA)-748 EVMS standard. The Federal Acquisition Regulation (FAR), which regulates purchasing of goods and services by the U.S. government, codified in the Code of Federal Regulations (CFR), provides the following requirements for an EVMS:

- 48 CFR 34.2031 Solicitation provisions and contract clause:

(c) The contracting officer shall insert a clause that is substantially the same as the clause at FAR 52.234-4, Earned Value Management System, in solicitations and contracts that require a contractor to use an EVMS. - 48 CFR 52.234-4 -Earned Value Management System:

As prescribed in 34.203(c), insert the following clause:

(a) The Contractor shall use an earned value management system (EVMS) that has been determined by the Cognizant Federal Agency (CFA) to be compliant with the guidelines in Electronic Industries Alliance Standard 748 (EIA-748) (current version at the time of award) to manage this contract. - OMB Circular No. A–11 (2019) Capital Programming Guide. [6, page 18]

I.5.5.4) Planning for Acquisition Management

The risk associated with the asset selected for consideration will determine the type of performance-based management system that should be used to monitor contractor performance in achieving the cost, schedule, and performance goals during the contract period. All major acquisitions with development effort will include the requirement for the contractor to use an Earned Value Management System (EVMS) that meets the guidelines in EIA Standard—748 to monitor contract performance.

Therefore, it is clear that the Federal government’s projects entailing construction of capital assets constitute major investments and thereby require an EVMS. Herein, a rigorous definition of a capital asset would be useful. This is discussed in detail in the OMB Circular No. A – 11 (2019) Capital Programming Guide (which uses the same language since June 2006), [6, page 2] that includes the following definition of capital assets,

Capital assets are land (including park lands), structures, equipment (including motor and aircraft fleets), and intellectual property (including software), which are used by the Federal Government and that have an estimated useful life of two years or more.

This definition continues [6, page 54] to include language relevant to government activities involving environmental cleanup:

Capital assets include the environmental remediation of land to make it useful, leasehold improvements and land rights; assets owned by the Federal Government but located in a foreign country or held by others (such as Federal contractors, State and local governments, or colleges and universities); and assets whose ownership is shared by the Federal Government with other entities.

OMB Continues [6, page 54] with some details, as well as specific examples:

Capital assets include not only the assets as initially acquired but also additions, improvements, modifications, replacements, rearrangements and reinstallations, and major improvements (but not ordinary repairs and maintenance). Examples of capital assets include the following, but are not limited to them:

- Office buildings, hospitals, laboratories, schools, and prisons;

- Dams, power plants, and water resources projects;

- Motor vehicles, airplanes, and ships;

- Satellites and space exploration equipment;

- Information technology hardware, software and modifications;

- Department of Defense (DOD) weapons systems; and

- Environmental restoration (decontamination and decommissioning efforts).

This paper will focus on operations activities relating to environmental remediation as well as operations at facilities after their construction is complete. Discussion of weapons platforms, motor vehicles, satellites, space exploration equipment, software development and other information technology are beyond the scope of this paper.

Additional Requirements for an Earned Value Management System in the United States Department of Energy

DOE Order 413.3B, Program and Project Management for the Acquisition of Capital Assets, [7, page C-10] also documents the requirement for the use of EVM on capital asset projects.

An EVMS is required for all projects with a Total Project Cost (TPC) greater than $50M. In accordance with FAR Subpart 52.234-4, a contractor’s EVMS will be reviewed for compliance with EIA-748C, or as required by the contract.

This is supported by NNSA Policy (NAP) NAP 413.2, Program Management Policy, that requires NNSA programs covered by DOE Order 413.3B to follow its requirements (including an EVM System). In addition, NAP 413.2 also references NNSA Business Operating Procedure (BOP) 06.07, Program Management Policy for Weapons and Strategic Materials Programs2 for guidance on life extension programs, [8, page AP1-2] which directs federal program managers to:

Implement project controls (such as a requirements management system, an integrated master schedule, and earned value management protocols) to track costs and synchronize execution of program scope across the nuclear security enterprise and with DOD.

A Capital Asset Project Versus an Operations Activity

Differentiating a Capital Asset from Operations Activities

It is important to distinguish a capital asset from an operations activity.

As described in OMB Circular No. A – 11 (2019) Capital Programming Guide, capital assets are distinguished from operations [6, page 54] as follows:

Capital assets exclude items acquired for resale in the ordinary course of operations or held for the purpose of physical consumption such as operating materials and supplies.

Also, it is important to understand that the life-cycle cost of a capital asset, as defined by OMB Circular No. A – 11 [6, page 54] requires inclusion of operating costs:

The cost of a capital asset is its full life-cycle costs, including all direct and indirect costs for planning, procurement (purchase price and all other costs incurred to bring it to a form and location suitable for its intended use), operations and maintenance (including service contracts), and disposal.

It is worth noting that projects for the construction of capital assets also inherently contain some operations activities. In general, these operations activities are managed in a project’s EVMS as routine undertakings without discretely measurable products: as level of effort. Examples of EM Program operations activities within a capital asset include: a portion of the overall site’s landlord activities and site services such as infrastructure maintenance, emergency management, safeguards and security; health and safety; and land management.

Defining an Operations Activity

As a general definition the definition from RP 10S-90 Cost Engineering Terminology for “operations” and an “operating cost” [5, page 82] are as follows:

Operation – Ongoing endeavor, or activities that utilize strategic assets for a defined function or purpose.

Operating Cost: The expenses incurred during the normal operation of a facility, or component, including labor, materials, utilities, and other related costs. Includes all fuel, lubricants, and normally scheduled part changes in order to keep a subsystem, system, particular item, or entire project functioning. Operating costs may also include general building maintenance, cleaning services, taxes, and similar items.

The first definition provides a general description of the term while the definition of operating cost provides good examples. More specific examples can be found when focusing on a specific industry. The AACE Recommended Practice, RP 107R-19, Cost Estimate Classification System – As Applied in Engineering, Procurement, and Construction for the Environmental Remediation Industries, describes the general stepwise environmental cleanup process within compliance of the major Federal laws such as the Resource Conservation and Recovery Act (RCRA) and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA). These projects often have an operations and maintenance phase [10, page 11]. In this phase, the cleanup project completes activities associated with operations and maintenance for the selected treatment or remediation alternative(s) as part of an environmental cleanup project. Operations activities in environmental projects, such as groundwater pumping and treatment, as well as radioactive waste, treatment, characterization packaging and disposition that end when clean up and/or waste treatment goals are met.

Looking within the EM program, a general listing of mission-related, stand-alone cleanup operating activities [9, page 4] is as follows:

Operating Activities: This category includes the retrieval, stabilization, packaging, storage, transportation and disposition of waste and nuclear materials; the operation of environmental remediation systems such as groundwater treatment systems; post-construction and post-closure care of remediated land burial sites; long-term environmental stewardship including environmental monitoring and institutional controls (e.g., maintaining a secure perimeter); as well as facility shutdown and deactivation activities designed to place the inactive structures, systems and components in a safe and stable configuration pending final decommissioning. Other EM activities in this category include: landlord activities and site services such as infrastructure maintenance.

It is important to note that the aforementioned is a partial list and that there are other EM activities that should be included in this category that are omitted to allow a focus on the most common operations. In order to provide a more comprehensive listing, EM Program mission-related, stand-alone cleanup operations activities also include: safeguards and security; emergency management; fleet (vehicle transportation) management; technology research, development and deployment; community-support, public outreach, regulatory support; and program management.

Operations Activities and Estimating Capital Asset Life-Cycle Costs

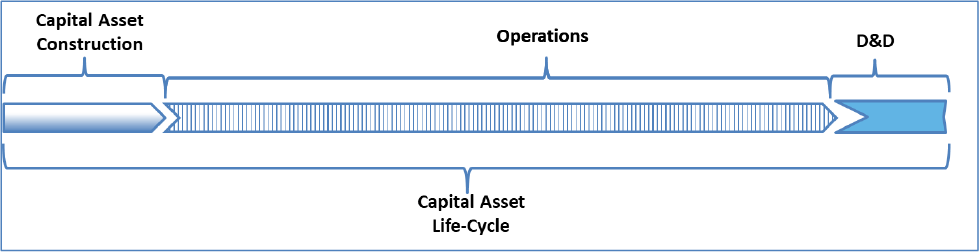

Operations activities such as those discussed above, are a key component for estimating the life-cycle costs for a capital asset. This can be seen in Figure 2 (below) which shows includes the costs for:

- Constructing a capital asset,

- Operations, as well as

- Decommissioning, deactivation, decontamination, demolition, dismantlement, and disposition (commonly referred to as D&D) [11, page 3] at the end of the it’s life cycle.

Figure 2– A General Description of the components of the life cycle cost of a capital asset which contains the sum of the construction of a capital asset, operations and D&D.

Maintaining a rigorous EVMS for operations activities is a good means for both measuring these costs as well as a tool to help archive historical records of these costs to be archived in a cost database, a useful tool for estimating future operating costs. Accurate life-cycle cost information is used to determine future year budget needs, project and program costs, manage changes in project scope and technical approach, as well as prioritize work activities. As an example, life-cycle cost analysis is required for making a business case for programmatic budget decisions. This is discussed in OMB Circular A-94, Guidelines and Discount Rates for Benefit-Cost Analysis of Federal Programs, which provides guidance for the methods to perform cost-benefits analyses for U.S. government programs. In addition, life-cycle cost estimate is critical for the evaluation of capital asset management. These life-cycle cost analyses are vital for a variety of budget processes, managing changes in project and program scope and technical approach, as well as to prioritize work activities. [9, pages 1-2]

Another example found in environmental projects operating within the CERCLA regulatory framework the selection of a specific remedy (or remedies) for the site clean-up is always done on a life-cycle cost basis. [10, page 8]

Operations Activity as Production

DOE Order 413.3B states that once construction of a facility is completed (also known as Critical Decision 4, CD-4), there is a transition to operations. This includes activities such as the development of operations and maintenance manuals, identification of the necessary budget, and the procurement of any materials required for initial operations. However, it is important to note that in certain cases (depending on the facility built) operations will also include initiation of production activities. Some examples of operations activities from the DOE EM Program as well as the DoD that involve production activities from completed facilities are provided below:

- Salt and sludge processing for dispositioning the waste in the Savannah River Site (SRS) High Level Waste (HLW) tank farms in Aiken, South Carolina. [12, pages 4-6.]

- Uranium Mill Tailings Disposal – the Moab Uranium Mill Tailings Remedial Action Project. [13, page 14];

- Transuranic (Radioactive) Waste Disposition Advanced Mixed Waste Treatment Project (AMWTP) located at the Idaho National Laboratory (INL), Idaho Falls, ID. [14, pages 3-4.]; and

- Destruction of Chemical Weapons (Demilitarization) – Various facilities [e.g., Pueblo Chemical Agent Disposal Pilot Plant (PCAPP), Blue Grass Chemical Agent Disposal Pilot Plant (BGCAPP) as well as the Umatilla Chemical Agent Demilitarization Facility (UMCDF) and four other completed projects] [3, pages 13-15.].

A significant point is that the aforementioned production/operations activities align to discrete EVM techniques facilitating their successful management. This has been discussed in a white paper produced by NDIA, “Earned Value Management in a Production Environment,” [16, pages 4-7]

The Government Accountability Office (GAO) Review of the EM Program’s Operation Activities

The GAO was directed by Congress to review the EM program, particularly its management of operations activities. This is significant because operations activities constitute the vast majority of the program’s work. As an example, in the fiscal year 2019 budget, operations activities accounted for over 75 percent of EM’s budget while capital asset projects accounted for under 20 percent of EM’s budget. Using the definition of operations discussed in this paper, a significant fraction of these activities may be classified as production, particularly where facilities within the EM Program process radioactive wastes for disposition.

In February 2019, GAO issued the results of their investigation as a report to Congress. “DOE Could Improve Program and Project Management by Better Classifying Work and Following Leading Practices,” (GAO-19-223) [1, page 44] that stated:

EM’s EVM systems for operations activities are not comprehensive, do not provide reliable data, and are not used by EM leadership to measure overall performance of the EM program.

Information from this report was also highlighted in the update to the GAO Cost Estimating and Assessment Guide (GAO-20-195G) [15, page 15]

As part of a response to this challenge in the GAO Report to Congress, the EM program organized a panel discussion Earned Value Management Systems for Operations to further address these challenge areas. The results of that panel discussion, as well as a review of the existing literature is provided in the remaining points that follow.

Topics to Consider for Creating an EVMS that Includes Operations Activities

Using Production Metrics to Measure Earned Value

As mentioned earlier, a significant portion of the operations activities in the DOE EM Program, as well as the DoD, involve production activities from completed facilities (e.g., the Moab Uranium Mill Tailings Remedial Action Project, the AMWTP and the destruction of chemical weapons (Demilitarization)). Production metrics should be an important component in the use of EVM for these types of activities.

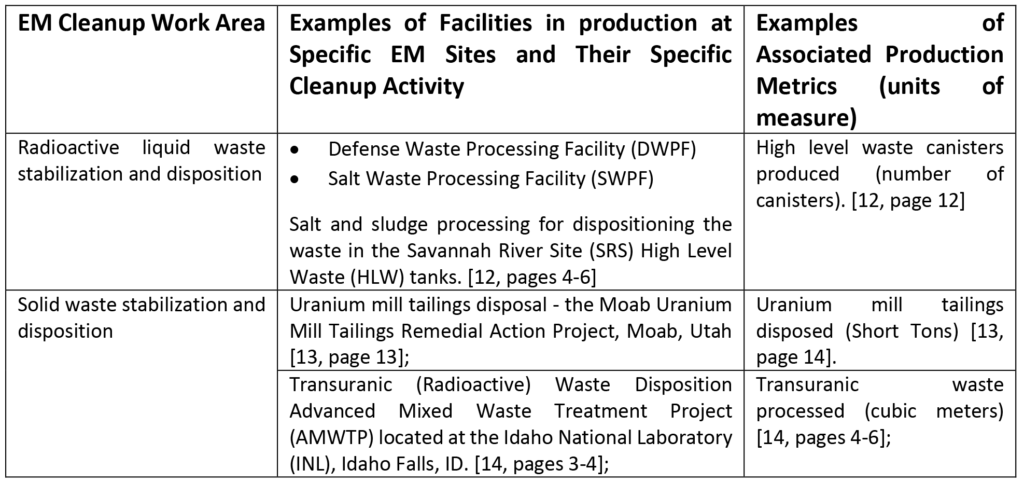

The EM Program divides its cleanup work into six work areas that sometimes include both operations activities and capital asset projects. A significant portion of the EM Program’s cleanup work is managed through operations activities that involve production in facilities at several sites dispositioning wastes. Some examples of these facilities, their connection to examples of the EM cleanup work area (specific cleanup activity), as well as examples of specific metric associated with those facilities are shown in table 1 (below):

Table 1–A listing of the EM cleanup activity with examples of sites with operating facilities dedicated to the disposition of both solid and liquid wastes. Also listed are the metrics associated with the production activities at these facilities.

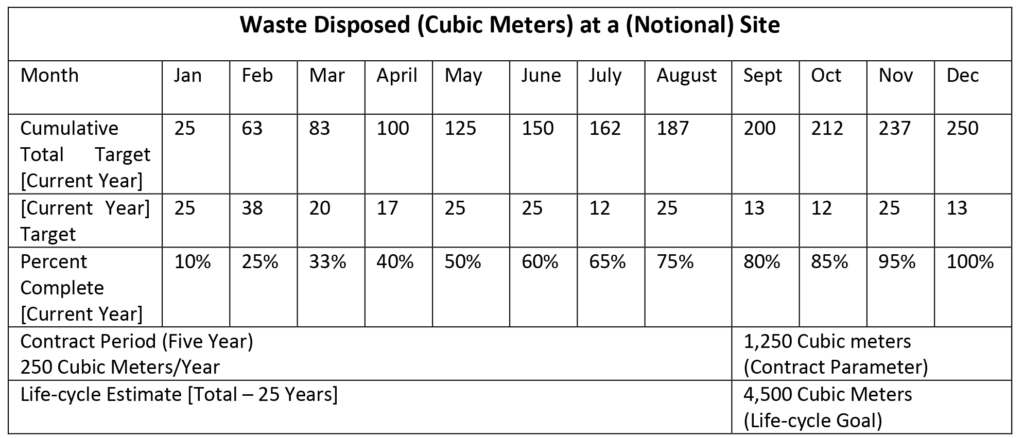

A key requirement for EVM is to measure the percentage of work completed, which is vital for determining the earned value at any point in time. The accuracy of the calculated earned value hinges on a reliable reporting system. In this case, a percentage completion rule that is based upon production metrics is recommended. As an example (shown in Table 2 below), predetermined annual completion milestones for each month of a specific year may be: 10, 25, 33, 40, 50, 60, 65, 75, 80, 85, 95 and 100 percent. This could reflect the metric targets for the first year in a five-year contract period of performance. This (notional) site has an estimated 4,500 cubic meters of waste, the contractor has developed a baseline where it will remove 250 cubic meters per year over a five-year period. The table below shows the first year listing the monthly targets as:

- Individual targets

- A cumulative target (a running total for the current year); and

- As a percent complete of the annual target,

Table 2. A listing of the targeted quantities of cubic meters of waste to be disposed at a (notional) site for (1) year, (2) a five-year contract period, and (3) its life-cycle. Also provided is a listing of monthly metrics for a calendar year both as cubic meters of waste as (1) a monthly target (2) as a cumulative total and (3) as well as percent complete.

The status of each active task completed in the effort reflected above is reviewed for a specific time period and updated. The extent of the work completed is measured for a given time period which is then compared to the planned value of the work for the period as well as the actual cost of the work. With these metrics, the project’s EVM is measured and updated.

As was discussed earlier in this paper, once construction of a capital asset is completed, the facility transitions to operations that (depending on the facility) may initiate production activities; which may continue years after that facility starts operations. An example would be the Moab Uranium Mill Tailings Remedial Action Project in Utah which started as a capital asset project (to establish physical infrastructure) with an approved baseline and a construction start in August 2008. The Moab Project then transitioned to an operations activity program in 2010, initiating the transport and disposal of uranium mill tailings and other contaminated materials, collectively known as residual radioactive material currently scheduled to end in 2025. For this program, the production metric: the disposal of uranium mill tailings is distributed over a 15-year period. This metric is subject to a wide variety of systemic variables (e.g., funding variations) as well as site-specific risks (e.g., a rockslide near the railroad area that occurred in in November 2014). [13, pages 14-15] Therefore, operations activities in the EM Program, in particular those involving production, as described in the aforementioned GAO report (GAO-19-223), can be readily quantified, measured, tracked, reported, and managed (including addressing risks) for a given performance period (spanning a number of reporting periods over many years).

The Challenge of Minimizing Level of Effort (LOE) Activities

A significant finding in the GAO Report on Operations Activities at DOE EM Sites [1, page 39] involves how activities are categorized within an EVMS:

- A large portion of the work is categorized as level of effort which has limited utility for EVM.

This requires a clear discussion of how activities involving production (discussed above) are categorized in an EVMS [16, pages 20-21]: production support labor is defined as all the other functional labor activities that assist, support or inspect the manufacturing labor efforts (e.g., tooling, quality, production control, industrial engineering, design engineering, manufacturing engineering, manufacturing supervision and other related disciplines). These activities are treated as level of effort (LOE) as it is not known when support will be needed and therefore it cannot be discretely planned. LOE work:

- Has the same budgeting requirements as discrete work;

- At a given time, Earned Value = Planned Value (regardless of the amount of work performed);

- Has to be scheduled with a start and finish date; and

- Lacks any milestones that could be used to measure performance.

This description of LOE, is also consistent to that given in RP 79R-13, Level of Effort Planning and Execution on Earned Value Projects – Within the Framework of EIA-748. [17, pages 2-3.] In addition, although these LOE tasks may have discrete deliverables (e.g., monthly reports), they do not represent physical progress of readily measured (i.e., discrete) efforts. Budget is scheduled and distributed over the period of performance, however, when an LOE task is performed during a given period, the value budgeted for that task is always claimed.

Also listed in RP 79R-13, [17, pages 2-4] is a possible solution to this challenge: thoroughly examine all work scope classified as LOE within a project or program with a goal and see if it can be reclassified into one of the two following categories:

- Discrete Effort – defined as “Tasks that have a specific measurable end product or end result” Discrete work has defined products. Discrete work is measurable and can be broken into steps or quantifiable tasks, each of which can be budgeted based on resources required to complete the work.

- Apportioned Effort –defined as: “An earned value technique in which status is assessed consistent with a discretely measurable base task(s). The earned value percent complete of the base effort is used to status the apportioned effort work package. Apportioned effort is technically related and time-phased proportionally to the based unit designated”

Lastly, RP 79R-13 recommends that LOE activities should be cordoned off as separate within its own control account (CA). Otherwise, LOE activities can distort the true performance of the CA’s EV data. Therefore, if LOE is embedded with discrete work activities in a CA, it should be reorganized to remove the LOE. [17, page 4]

An example of shifting the application of LOE from an environmental activity to apply apportioned effort instead (as the Earned Value Technique-EVT), is the use of radiation safety technicians-a necessary part of an environmental cleanup project. Often such activity is designated as LOE because it is not known precisely when the technician’s support will be needed and therefore it cannot be discretely planned (16, page 21). However, a portion of the radiation technician’s work can be apportioned when associated with the characterization, packaging and dispositioning radioactive waste as shown in Table 2 (see above). Therefore, the radiation safety technician’s portion of the work relating to the disposition of radioactive waste can be more discretely measured.

Challenges in Calculating an Accurate Estimate at Completion (EAC)

The estimate at completion (EAC) is the estimated total cost for the authorized work scope, defined as the sum of the actual cost of work performed (AC) to date plus an objective estimated cost to complete (ETC) of the remaining work scope. [18 page 3] For operations activities within a program baseline establishing an accurate EAC is challenging. As demonstrated by a large portion of the EVM literature, EVM works well when there is an end point and deliverable completed at the end of a discrete project life-cycle (e.g., a facility or weapons platform). However, many operations activities can continue for an extended period far exceeding the duration required to construct an actual facility. For such operations activities, their associated “end points” are not defined by the completion of a specific deliverable (e.g., construction of a facility). Instead, the operations activities are defined by the duration of their associated work scope defined within a contract period (or some other discrete period of performance). As an example, in the case of the Moab Project, the necessary capital project has already been completed several years ago. Currently, there is a specific quantity of uranium mill tailings required to be retrieved and dispositioned over a specific contract period of performance (an estimated 15-year period over the life-cycle of operations starting in 2010 and projected to end in 2025). [13, page 13-14] Estimating an accurate full EAC to disposition the mill tailings over a contract period (as distinct from the remaining life-cycle) can be a challenge to accurately and effectively communicate as part of the standard reporting requirements for an EIA 748 compliant system. In addition to conventional challenges that environmental cleanup activities are prone to unique uncertainties, [19, page 4] including:

- Uncertainties concerning the extent of the quantities and types of contaminants;

- Delayed site cleanup (often the only option considering limitations to available funding) resulting with increased contamination spread;

- The requirement for multiple regulatory approvals with potential changing requirements; and

- Unforeseen environmental science and technology challenges

These uncertainties have implications to establishing and maintaining accurate EACs and executable performance baselines for environmental cleanup in general.

EVM Tailoring

In general, an EVMS has found effective application in capital asset projects. This can be seen in the following quote from Office of Management and Budget (OMB) whose mission is to assist the Executive Branch in carrying out their budgetary duties. OMB Circular A – 11 provides guidance for federal agencies to prepare their budget requests from Congress. A portion of OMB Circular No. A–11 (2019), Capital Programming Guide [6, page 15] discusses tailoring an EVM:

Implemented properly, an EVM system will measure progress against a baseline and provide an early warning of cost overruns and schedule delays. Most likely, a practical application of EVM will involve tailoring the principles to a project’s unique circumstances.

The GAO Cost Estimating and Assessment Guide (GAO-20-195G) discusses the possibilities for tailoring [15, page 217] an EVM (defining scope with a Work Breakdown Structure (WBS)) for short term and small dollar projects:

EVM can be tailored and ingrained into the culture to ensure that program cost and schedule goals are met for smaller or shorter projects; smaller projects will benefit from having the work scope defined by a WBS and having a detailed plan and schedule for accomplishing the work. Small-dollar projects still need to have a baseline in place to manage changes and variances and risk management plans to address issues.

In addition, the NDIA also produced White Paper EVMS Guideline Cross Reference Addendum [20. Page 2] which discusses tailoring a WBS: since typical manufacturing operations control accounts may not be created at the lowest level of the WBS. Therefore, the depth of a WBS may be tailored in a production environment.

Lastly, the Integrated Program Management Data and Analysis Report (IPMDAR) Data Item Description (DID) Tailoring and Implementation Guide provides general guidance for tailoring an EVMS. Some examples [20, pages 53, 75-80] of what can be changed with an EVM Tailoring Approach:

- Rigor of Variance Analysis – Variance Thresholds.

- Formality of Change Control process – Work Authorization.

- Deployment of Charge Numbers – Cost Collection Level.

- Level of Reporting (e.g., Level of Reporting (Work package, Control Account, WBS, etc.).

- Contract Performance Report (CPR) Formats.

- Reporting Frequency (Monthly, Weekly, Quarterly, Annually, Incremental, Upon Request).

The Use of EVM for Operations in Shipbuilding

A review of the literature shows that there is substantial use of EVM applied to operations in the shipbuilding industry.

A RAND corporation study done for the United Kingdom’s Defense Procurement Agency (DPA), discusses how shipbuilders track project and program progress [22 page 31] “Nearly all shipbuilders use earned value management to monitor the progress of production and design.” This point was elaborated upon in an article presented at an AACE meeting in 2018 [23, page 5]: “It is common practice in shipyards to follow the ANSI/EIA earned value management (EVM) standard in order to comply with federal contract requirements, especially for military ships. The budgeting process, accounting considerations, and governance features are well-defined in this standard.” Lastly, the NDIA White Paper EVMS Guideline Cross Reference Addendum which discusses specific differences between a development and production effort or a shipbuilding environment [21, page 1] details the relevant differences between the environments required for tailoring for the shipbuilding industry. These three publications provide an overview for the effective use of EVM within the shipbuilding industry.

A specific example of EVM tailoring can be found discussing managing a WBS. Canadian surface ship and submarine owners provide a common framework for the overall planning and control of an entire ship life-cycle; this framework, called a ship work breakdown structure (SWBS) has to be mapped properly to the WBS, and the organizational breakdown structure (OBS) [23, page 5]. The NDIA discussed very similar processes for an Expanded Ship WBS (ESWBS) that must be mapped to the externally reported WBS [21, pages 2-3]. In addition, the RAND study there is a strong requirement to limit level of effort activities [22 page 18]. A good example of limiting LOE in a shipbuilding EVMS had also been provided: when production support tasks that cannot be readily measured on their own, or which cannot be broken down into discrete work packages but which are related to the planning and performance of other measured effort, are measured using the apportioned effort technique [22, pages 20-21].

The uses of EVMS for operations that is mature within the shipbuilding industry can serve as a resource for lessons learned and examples for implementation EVMS for Operations for the Department of Energy EM Program. This is especially interesting in areas where the shipbuilding industry deals with environmental issues such as when the United States Navy has to dispose of its obsolete National Defense Reserve Fleet vessels in a manner that maximizes financial returns to the US. However, the ship dismantling must be done in an environmentally safe manner due to concerns about the environment and worker safety and health [24, page 1].

Conclusion

This paper describes the advantages and requirements for an earned value management system as well as a description of the requirements of an EVMS for government programs.

Along with the requirements for an EVMS for government projects, this paper also provides a detailed definition of capital asset projects, as distinct from operations activities, including specific examples within the EM Program. Also included is a discussion of some of the challenges that impact the effective use of EVMS for operations activities (especially production) including a discussion of the uncertainties involved with measuring operations in an environmental cleanup program such as:

- Uncertainties with the extent of the quantities and types of contaminants;

- Delayed site cleanup (often the only option considering limitations to available funding) resulting in greater contamination spread as well as increased scope; and

- A complex regulatory framework;

An effective EVMS can provide effective performance controls, an understanding of operations activities, as well as a means to accurately record their historical costs which are required for estimating accurate life-cycle costs. Life-cycle costs are vital for determining budget priorities, managing changes in project scope and technical approach, as well as to prioritize work activities.

In addition, there is discussion of some of the practices that would best enable the use of EVM to measure operations activities, including:

- EVM Tailoring;

- Using Production Metrics; and

- Minimizing the use of Level of Effort Activities.

Lastly, this paper discusses some of applications of an EVMS for operations that is mature within the shipbuilding industry.

References

- US General Accountability Office. “DOE Could Improve Program and Project Management by Better Classifying Work and Following Leading Practices,” GAO-19-223 (February 2019).

- Planning the Future: Methodologies for Estimating U.S. Nuclear Stockpile Cost, Frank Douglas Lewis; Cash Fitzpatrick; Matt Proveaux; Cole Lillard; William P. Todd, Cost Engineering, Vol. 58, No. 05, AACE International, Morgantown, WV, 2016.

- Remediation of Buried Chemical Warfare Materiel, National Research Council 2012. Washington, DC: The National Academies Press; (Taken from the internet January 1, 2021: https://doi.org/10.17226/13419)

- Earned Value Management Systems for Operations – A Panel Discussion a presentation given at, Virtual Workshop – sponsored by U.S. Department of Energy, Office of Environmental Management, Office of Project Management (EM-5.22), Washington, DC, October 21, 2020.

- AACE International, Recommended Practice No. 10S-90, Cost Engineering Terminology, Morgantown, WV: AACE International, Latest revision.

- The United States Government Capital Programming Guide (a supplement to the United Government Office of Management and Budget, Circular A–11: Planning, Budgeting, and Acquisition of Capital Assets).

- DOE Order 413.3B, Program and Project Management for the Acquisition of Capital Assets, Change 6, January 12, 2021. ([Taken from the internet January 1, 2021: http://www.emcbc.doe.gov/Office/ProjectManagement]

- BOP 413.5, Program Management Policy for Weapons and Strategic Materials Programs

[Taken from the internet February 6, 2021: https://directives.nnsa.doe.gov/bop/bop-0413-005.] - U. S. Department of Energy (DOE) Office of Environmental Management (EM) Cost Estimate Development Handbook, EMCBC-OOCE G 002 Revision 1, August 22, 2019 [Taken from the internet January 1, 2021: http://www.emcbc.doe.gov/Office/ProjectManagement]

- A Discussion of the Cost Estimate Classification System: As applied in the Engineering, Procurement, Construction and Operations for the Environmental Remediation Industries, Dan Melamed, CCP EVP; Bryan A. Skokan, PE CCP; Gregory Mah-Hing, PE; Rodney Lehman; Jake Lefman, 2020 AACE International Transactions, EST-3542, AACE International, Morgantown, WV, 2020.

- Interstate Technology & Regulatory Council (ITRC) Technical and Regulatory Guidance Document: Decontamination and Decommissioning of Radiologically Contaminated Facilities (RAD-5) 2008; [Taken from the internet March 20, 2021]: https://itrcweb.org/GuidanceDocuments/RAD5.pdf

- U. S. Department of Energy (DOE) Savannah River Site Liquid Waste Plan SRR-LWP-2009-00001 Revision 21, January 2019 [Taken from the internet January 24, 2021: https://www.energy.gov/sites/prod/files/2019/05/f62/SRS-Liquid-Waste-System-Plan-January-2019-0.pdf]

- Managing a Large Mill Tailings Cleanup Project, Donald R. Metzler, 2015 AACE International Transactions, OWN.2057, AACE International, Morgantown, WV, 2015

- Progress and Lessons Learned in Transuranic Waste Disposition at the Department of Energy’s Advanced Mixed Waste Treatment Project, J. D. Mousseau, S. C. Raish, F. M. Russo, WM’06 Conference, February 26 – March 2, 2006, Tucson, AZ

- US General Accountability Office. ” Cost Estimating and Assesment Guide, Best Practices for Developing and Managing Capital Program Costs,” GAO-20-195G (March 2020).

- Earned Value Management in a Production Environment, Production Earned Value Management Working Group, Adams et al, National Defense Industrial Association, October 10, 2011.

- AACE International, Recommended Practice No. 79R-13, Level of Effort Planning and Execution on Earned Value Projects – Within the Framework of EIA-748, Morgantown, WV: AACE International, Latest revision.

- AACE International, Recommended Practice No. 80R-13, Estimate at Completion (EAC), Morgantown, WV: AACE International, Latest revision.

- Tailored Risk Management Assessment Tool, Bryan Skokan, Dan Melamed, Rodney Lehman, R., and Jake Lefman, RISK.1284, , 2013 AACE International Transactions, AACE International, Morgantown, WV. 2013.

- Integrated Program Management Data and Analysis Report (IPMDAR) Data Item Description (DID) Tailoring and Implementation Guide (DI-MGMT-81861B) issued 12 March 2020.

- White Paper EVMS Guideline Cross Reference Addendum, Production Earned Value Management Working Group, Adams et al, National Defense Industrial Association, January, 2015.

- Monitoring the progress of shipbuilding programmes: how can the Defence Procurement Agency more accurately monitor progress? Mark V. Arena, John Birkler, John F. Schank, Jessie Riposo, and Clifford A. Grammich. 2005, RAND Corporation (Taken from the internet April 8, 2021: https://www.rand.org/pubs/monographs/MG235.html).

- Integrated Cost and Schedule Model for Shipbuilding Projects, Ahmad Emam, 2018 AACE International Transactions, CSC-2855, AACE International, Morgantown, WV, 2018.

- Ship Dismantling Cost Review, Robert C. Creese; Pooja Sibal, 2001 AACE International Transactions, EST.03, AACE International, Morgantown, WV, 2001.

- RP 107R-19: Cost Estimate Classification System – As Applied in Engineering, Procurement, and Construction for the Environmental Remediation Industries, Morgantown, WV: AACE International, Latest revision

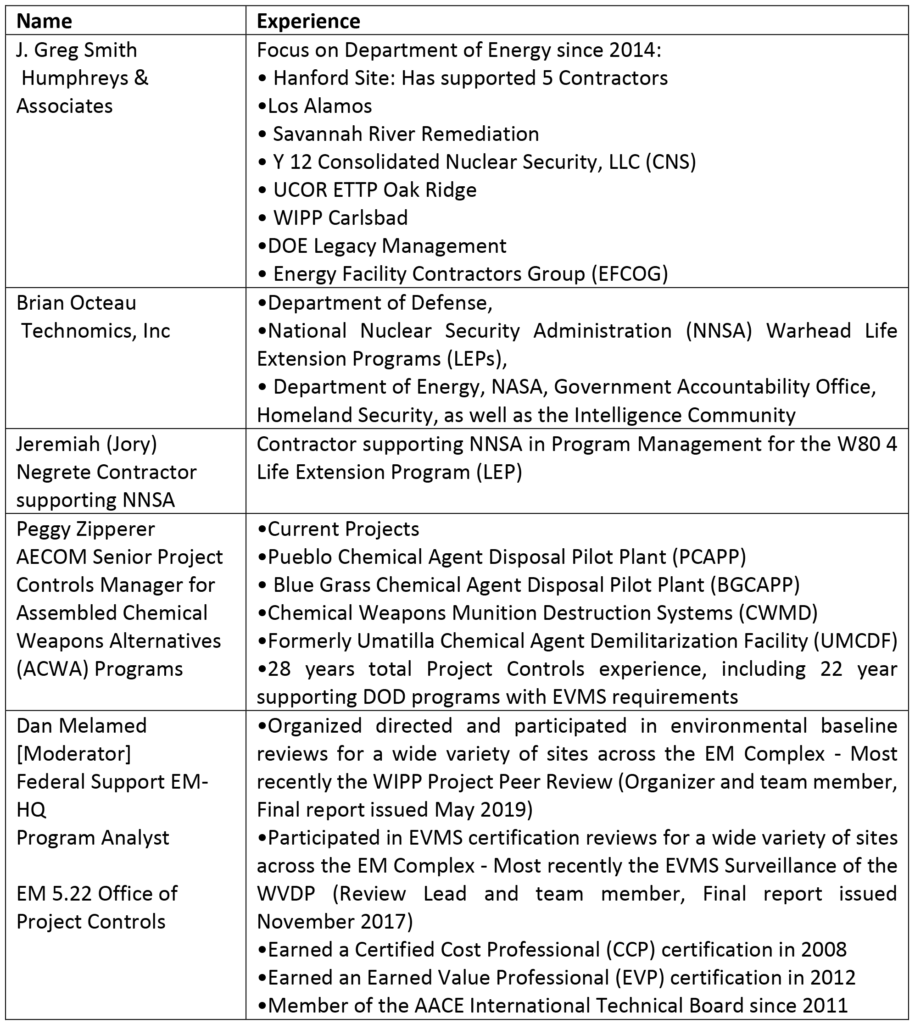

Appendix 1

A listing of the Members of the Panel for EM Program’s Earned Value Management Systems for Operations Activities

Table 3–Members of the panel Earned Value Management Systems for Operations along with a summary of their experience.

Rate this post

Click on a star to rate it!

Average rating 4.3 / 5. Vote count: 7

No votes so far! Be the first to rate this post.

To get aware on EVM

Great research

@Dan, Crystal, Lisa, and Rodney;

You may want to compare what you’ve done to what/how our client, Freeport McMoran Indonesia, which is a US-based operational company, set up their EVM system, which documented savings of 65 million USD over a 4 year period?

Ridwan Wibiksana, CCP, PMP- https://pmworldlibrary.net/wp-content/uploads/2013/01/PMWJ2-Sep2012-WIBIKSANA-EVM-Adapted-for-UndergroundMining-StudentPaper.pdf

PTMC Team- https://build-project-management-competency.com/ptmc-training-standards-and-specifications-individual/

The only two major differences that I can see are:

1) When we set up the system for Freeport, we did not use an S-Curve but simply took the Annual CAPEX or OPEX budget and allocated it over the fiscal year (Approved Budget/365 days/3 shifts = per shift BCWS). This produced a single straight line, not an S Curve. (No ED/LD Curves)

2) In support of eventual BIM implementation, we adopted CSI’s Omniclass as the STANDARDIZED WBS/CBS coding structures. (Tables 21 and 22)

And the only ENABLER that was necessary to make this work was Freeport had an accounting system that supported the use of Activity Based Costing. Using ABC/ABM we were able to generate online progress reports within 2-3 hours after the close of each shift and we were able to report “traditional” EVM metrics at the Program, Individual Projects, Shift and even Crew Level. We were also able to report process control and process capability using 3 Sigma SPC charts. (Go HERE https://build-project-management-competency.com/1-4-1-11-unit-11/ and see Figures 15-21, Figures 43-49 and the Case Study from Figure 88.

I can only urge AACE to stop looking ONLY at how the US Government uses Earned Value by going back to our Cost Engineering Roots and embracing EVM as it evolved on the factory floors of 18th Century Industrial Revolution as a “pay for performance” or “incentive payment scheme”. Download Gillette and Dana’s 1909 book “Cost Keeping and Management Engineering: A Treatise for Engineers, Contractors and Superintendents Engaged in the Management of Engineering Construction” https://books.google.co.id/books?redir_esc=y&id=zO-ADudj-R8C&focus as that is the “best tested and PROVEN” approach used by nearly all PRIVATE SECTOR CONTRACTORS even today.

Here is a follow on paper that we’ve published on the subject of Earned Value Management as the private sector has been using it for over 120 years.

https://pmworldlibrary.net/wp-content/uploads/2022/09/pmwj121-Sep2022-Giammalvo-origins-and-history-of-evm-a-contractors-perspective.pdf

This tested and PROVEN model is based on Halbert Powers Gillette and Richard Turner Dana’s 1909 book “Cost Keeping and Management Engineering: A Treatise for Engineers, Contractors, and Superintendents Engaged in the Management of Engineering Construction. https://books.google.com.sg/books/about/Cost_Keeping_and_Management_Engineering.html?id=zO-ADudj-R8C&redir_esc=y

This application of EVM is still in use today by anyone who “cost, prices, bids and bills” for work based on the “Unit in Place” method.